Minifactories: The Micro-Factories Revolutionizing Production

The future of manufacturing is shrinking. Forget sprawling industrial complexes – the rise of mini-factories is ushering in a paradigm shift, bringing production closer to consumers and disrupting how goods are made. These agile, localized production units are reshaping industries, from food and pharmaceuticals to aerospace and fashion. Buckle up, we’re diving into the fascinating world of mini-factories!

Miniaturization with a Mighty Impact

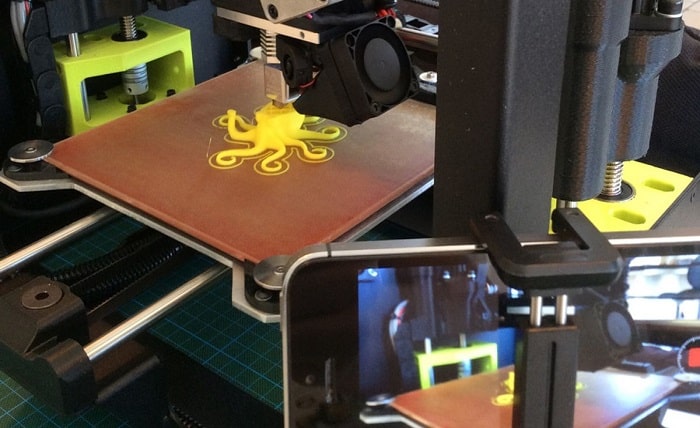

Mini factories, as the name suggests, are compact manufacturing facilities optimized for flexibility and efficiency. Typically occupying spaces as small as shipping containers or repurposed warehouses, they operate with modular equipment and digital fabrication technologies like 3D printing, robotics, and AI. This miniaturization packs a punch, offering several key advantages:

Location Agility: Gone are the days of centralized, inflexible production chains. Minifactories can be strategically located near resources, markets, or specific customer needs, ensuring faster delivery and responsiveness.

Reduced Environmental Footprint: Smaller facilities translate to lower energy consumption and waste generation. Additionally, localized production minimizes transportation emissions, contributing to a greener supply chain.

Personalized Production: The adaptability of mini-factories allows for on-demand manufacturing and customization. Imagine shoes or medicine tailored to your unique needs, produced right in your community!

Enhanced Innovation: The collaborative, experimental environment fosters rapid prototyping and testing, accelerating the development of new products and processes.

The Mini factory Ecosystem

The minifactory revolution isn’t a solo act. It thrives on a diverse ecosystem of players:

Technology Providers: Companies like miniFactory and Desktop Metal are paving the way with innovative 3D printers and robotized production systems.

Software Developers: Digital platforms for design, workflow management, and data analysis are crucial for optimizing operations and connecting mini-factories.

Material Suppliers: Sustainable, high-performance materials compatible with digital fabrication are essential for diverse product creation.

Local Communities: Mini factories can empower local economies by creating jobs, supporting local businesses, and fostering innovation hubs.

The Mini factory Landscape

While the potential of mini-factories is immense, implementing them requires careful consideration:

Identifying the Right Application: Not all industries or products are suited for minifactories. Assessing market demand, production complexity, and cost-effectiveness is crucial.

Building the Talent Pool: Operating these high-tech facilities demands a skilled workforce trained in advanced manufacturing technologies and data analysis.

Securing Investment: Integrating new technologies often necessitates upfront investment. Exploring grants, partnerships, and innovative financing models can be key.

Case Studies: Mini factories in Action

Let’s see how mini-factories are already transforming industries:

Food & Beverage: Local breweries and food cooperatives are utilizing mini-factories to create fresh, customized products with minimal waste.

Medicine & Bioprinting: Pharmaceutical companies are experimenting with minifactories for on-demand production of personalized medications and medical devices.

Aerospace & Automotive: The ability to produce lightweight, complex parts near assembly lines makes minifactories attractive for these industries.

Conclusion

The rise of mini-factories is not just a technological trend – it’s a cultural shift towards decentralization, sustainability, and personalized production. While challenges remain, the potential benefits for businesses, communities, and the environment are undeniable. As mini-factories continue to evolve and become more accessible, prepare to witness a future where production happens not just in mega-factories, but in your neighborhood, tailored to your needs – a truly micro-revolution in the making.

FAQ

1. Are minifactories replacing traditional factories?

No, they are not replacements, but rather complementary options. Minifactories excel in flexibility and customization, while traditional factories remain crucial for high-volume production.

2. What are the job implications of minifactories?

While some traditional jobs may be replaced, new opportunities emerge in areas like engineering, software development, and data analysis. Additionally, minifactories can create local jobs and strengthen communities.

3. Are minifactories environmentally friendly?

Their smaller size and reduced transportation needs make them inherently greener than traditional factories. However, sustainable material choices and energy efficiency remain key considerations.

4. Can I start my own minifactory?

The barriers to entry are lowering, but careful planning, market research, and access to technology and investment are still required.

5. Where can I learn more about minifactories?

Industry associations, online communities, and events dedicated to digital manufacturing and minifactories can provide valuable resources and insights.